When it comes to solar installations, every component counts, and that includes the wiring. Solar systems require materials that can endure various environmental factors while providing efficient and reliable electrical conductivity. This is where tinned stranded copper wires shine.

The Anti-Corrosion Advantage of Tinning

The superior electrical conductivity of copper is well-documented, but less discussed is its susceptibility to corrosion. Left unprotected, copper reacts with the elements, leading to oxidation – a process that compromises both its performance and longevity. This is where tinning comes into the picture. Applying a thin layer of tin over copper forms a shield against the very environmental challenges that cause corrosion. Tin is less reactive than copper and does not oxidize as readily, which means it can prevent the degradation of the copper beneath.

This protection is not just against moisture but extends to a variety of corrosive agents. Whether it's the salt in coastal air or acids in industrial environments, the tin plating stands guard, ensuring the copper continues to perform its primary function – conduct electricity effectively.

How Tinning Enhances Copper

The process of tinning copper involves coating it with a thin layer of tin either by hot-dipping the copper in melted tin or through electroplating. This not only improves its resistance to corrosion but also augments its solderability. Tin has a lower melting point than copper, which makes it easier to solder, ensuring stronger connections in the assembly of solar components.

Moreover, tinned copper can withstand high temperatures, which are often encountered in solar applications. High temperatures can accelerate the corrosion of bare copper; the tin coating acts as a thermal barrier, reducing the rate of corrosion and sustaining the integrity of the wire over time. This is especially crucial for rooftop solar installations that can reach scorching temperatures during peak sun hours.

Enhanced Flexibility and Efficiency with Stranded Design

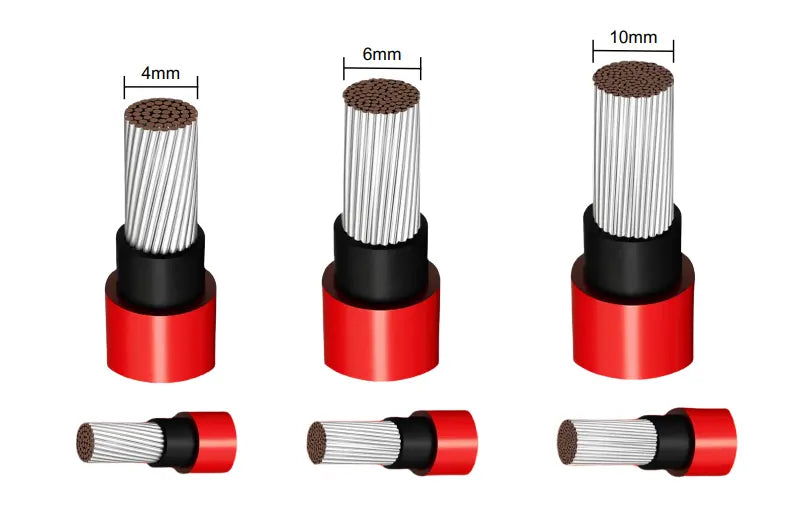

Solar installations often demand wiring through tight spaces and around tricky corners. Stranded copper wire, composed of numerous small strands of copper twisted together, provides the necessary flexibility. This design allows for easy bending and routing through the intricate pathways within solar panel arrays and connection systems. It also means that when your panels move to track the sunlight, the wires won’t crack under the stress of movement, maintaining an uninterrupted flow of energy.

Stranded wires have a larger surface area than solid wires of the same diameter. This translates to lower resistance and less energy lost as heat, making them energy-efficient choices for your green power system. Combined with the anti-corrosive properties of tinning, stranded copper wires ensure that the energy produced by your solar panels is delivered where it’s needed with minimal loss.

The Bottom Line

If you're in the process of assembling a solar installation or considering an upgrade, remember the critical role of high-quality, durable wiring. It's not just about the panels and inverters; the wires are the silent workhorses ensuring your system's reliability and efficiency. Explore options that will fortify your setup against the elements and time, laying a solid foundation for your sustainable energy journey.

Ready to enhance your solar setup or curious about the best options for your system? Dive deeper into our resources or reach out to our team for expert guidance. Together, let's harness solar energy with precision and care, empowering a greener tomorrow.