In the world of electrical wiring, it’s essential to use the right type of wire for the specific application to ensure safety and efficiency. Two common types of wires that often get confused are USE-2 wires and PV wires. Although they might appear similar and are used in solar power systems, they have distinct differences and applications. Understanding these differences is crucial for electricians, solar installers, and DIY enthusiasts.

USE-2 Wires: Overview and Applications

USE-2 (Underground Service Entrance) wires are designed specifically for underground installations. They are robust, insulated cables suitable for direct burial in the ground. Here are some key characteristics of USE-2 wires:

- Insulation Material: USE-2 wires are insulated with thermoset materials like cross-linked polyethylene (XLPE), which makes them resistant to heat, moisture, and chemicals. This insulation is durable and capable of withstanding harsh underground conditions.

- Voltage Rating: USE-2 wires are typically rated for 600 volts, which is adequate for many residential and commercial underground electrical service entrances.

- Temperature Rating: They can operate in temperatures up to 90°C in wet or dry locations, making them versatile for various environments.

- Applications: These wires are commonly used for underground service entrances, feeder circuits, and branch circuits. They are not suitable for above-ground use unless protected from physical damage and UV radiation.

PV Wires: Overview and Applications

PV (Photovoltaic) wires are designed specifically for solar power systems, connecting solar panels to inverters and other components of the solar array. Here are some distinguishing features of PV wires:

- Insulation Material: PV wires are insulated with materials like cross-linked polyethylene (XLPE) or thermoplastic elastomer (TPE), which provide excellent resistance to sunlight, moisture, and temperature extremes.

- Voltage Rating: PV wires have higher voltage ratings, typically up to 1000 volts or more, suitable for the higher voltages encountered in solar power systems.

- Temperature Rating: They can operate in temperatures ranging from -40°C to 90°C, ensuring performance in various environmental conditions.

- UV and Weather Resistance: PV wires are designed to withstand long-term exposure to sunlight and weather, making them ideal for rooftop and outdoor solar installations.

- Applications: These wires are used in solar panel arrays, connecting modules, inverters, and other solar equipment. They are essential for ensuring the efficient and safe operation of photovoltaic systems.

Key Differences Between USE-2 and PV Wires

- Application: USE-2 wires are intended for underground electrical services, while PV wires are designed specifically for solar power systems.

- Voltage Rating: PV wires have higher voltage ratings than USE-2 wires, making them suitable for the higher voltages in solar installations.

- UV Resistance: PV wires are designed to withstand prolonged exposure to sunlight, unlike USE-2 wires, which need protection from UV rays if used above ground.

- Insulation Materials: While both types of wires may use similar insulation materials, PV wires often have additional features like enhanced UV resistance and flexibility to handle the demands of solar power systems.

- Regulatory Standards: PV wires must meet specific standards for solar applications, such as UL 4703 and EN 50618, whereas USE-2 wires comply with standards for underground service entrance cables.

Misleading Marketing Practices

Some companies market USE-2 wire as PV wire, which is misleading and potentially dangerous. This practice can lead to significant safety issues and operational inefficiencies in solar power systems. Here are a few reasons why this is problematic:

- Inadequate UV Resistance: USE-2 wires lack the necessary UV resistance required for PV applications. When exposed to sunlight for extended periods, USE-2 insulation can degrade, leading to potential electrical failures and safety hazards.

- Voltage Compatibility: Solar power systems often operate at higher voltages than what USE-2 wires are rated for. Using a wire with an inadequate voltage rating can result in overheating, insulation breakdown, and fire risks.

- Regulatory Non-compliance: PV wires need to meet specific regulatory standards to be safe and effective for solar applications. EN 50618 specifies the requirements for single-core cables used in photovoltaic systems. Using USE-2 wire in place of PV wire may violate these standards, leading to legal and insurance complications.

- Misleading Consumers: Marketing USE-2 wire as PV wire misleads consumers and installers, leading them to believe they are using a product specifically designed for solar applications when, in fact, they are not.

Relevant Standards: EN 50618 and H1Z2Z2-K Cables

EN 50618 is the European standard that specifies the requirements for single-core cross-linked insulated cables used in photovoltaic systems. H1Z2Z2-K cables are a specific type of PV wire that conforms to the EN 50618 standard, indicating that they are ready for use in solar applications. Here are some key points from EN 50618 and H1Z2Z2-K cables:

- Voltage Rating: Cables must be rated for a nominal voltage of 1.5 kV DC.

- Temperature Range: Cables must be able to operate in a temperature range from -40°C to +90°C, with a maximum conductor temperature of +120°C.

- UV Resistance: Cables must have insulation that can withstand prolonged exposure to sunlight and UV radiation without degradation.

- Mechanical Properties: Cables must be robust enough to withstand mechanical stresses, such as those caused by bending and abrasion during installation and operation.

- Markings: Cables must be clearly marked with relevant information, including the manufacturer's name, the standard number (EN 50618), and other specifications to ensure traceability and compliance.

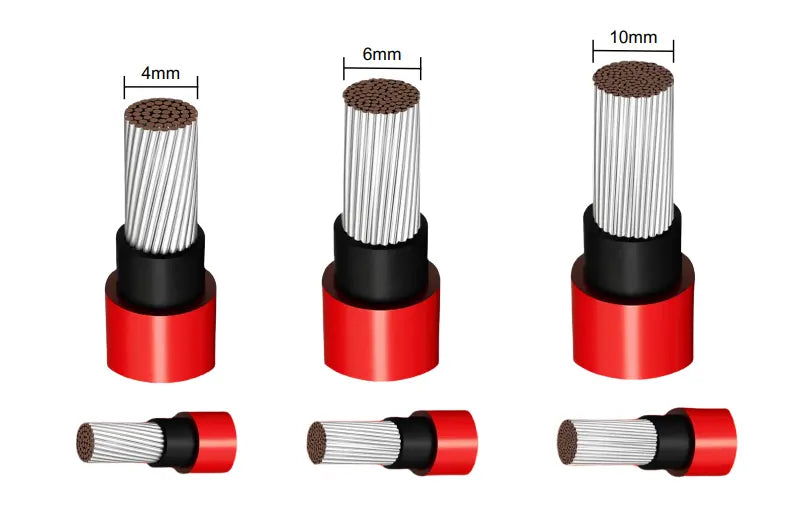

- Insulation and Sheath: H1Z2Z2-K cables are made from cross-linked polyethylene (XLPE), providing excellent thermal and mechanical properties.

- Flexibility: H1Z2Z2-K cables are designed to be flexible and easy to install, even in challenging environments.

Benefits of Two Layers of Insulation in PV Cables

PV cables like H1Z2Z2-K often feature two layers of insulation for enhanced safety and durability:

- Outer Layer of Halogen-Free Thermoset Polyolefin:

- Halogen-Free: Reduces the release of toxic gases in the event of a fire, improving safety.

- Thermoset Polyolefin: Provides excellent resistance to UV radiation, weather, and mechanical stress, making it ideal for outdoor applications.

- Inner Layer of Cross-Linked XLPE:

- Cross-Linked Polyethylene (XLPE): Offers superior thermal resistance and mechanical strength, ensuring long-term durability and reliability under high temperatures and electrical loads.

Conclusion

Choosing the correct type of wire is crucial for the safety and efficiency of electrical and solar power systems. While USE-2 wires are ideal for underground installations, PV wires, such as those conforming to EN 50618 and H1Z2Z2-K, are specifically designed for solar power applications with higher voltage ratings and superior UV resistance. Misleading marketing practices that sell USE-2 wires as PV wires can result in severe safety hazards and regulatory issues. Standards like EN 50618 ensure that PV wires meet the necessary requirements for safe and efficient solar installations. The dual insulation layers in PV cables, with an outer layer of halogen-free thermoset polyolefin and an inner layer of cross-linked XLPE, provide enhanced safety and durability, making them ideal for photovoltaic applications. Always consult with a professional or refer to the National Electrical Code (NEC) and relevant standards like EN 50618 for guidance on the appropriate wire type for your specific application to ensure compliance and safety.